CAMWorks Additive Manufacturing is fully integrated into SOLIDWORKS and allows 3D models to be printed directly from SolidWorks.ĬAMWorks ShopFloor provides CNC (computer numerical control) machinists the ability to view solids models, view full simulations of CNC programs and edit machining data on the shop floor, without the need to purchase a full shop-floor CADCAM system. Multiple parts from the same assembly or different assemblies can be nested onto the build platform, which saves time and increases efficiency, and CAMWorks Additive Manufacturing automatically generates the build supports. With Version 2020, the CAMWorks Additive Manufacturing module, powered by Materialise, has extended 3D printing functionality to SolidWorks Assemblies. CAMWorks Version 2020 provides support for 3D printing of SolidWorks Assemblies, the CAMWorks ShopFloor product, intelligent probing functionality and automatic tab machining.

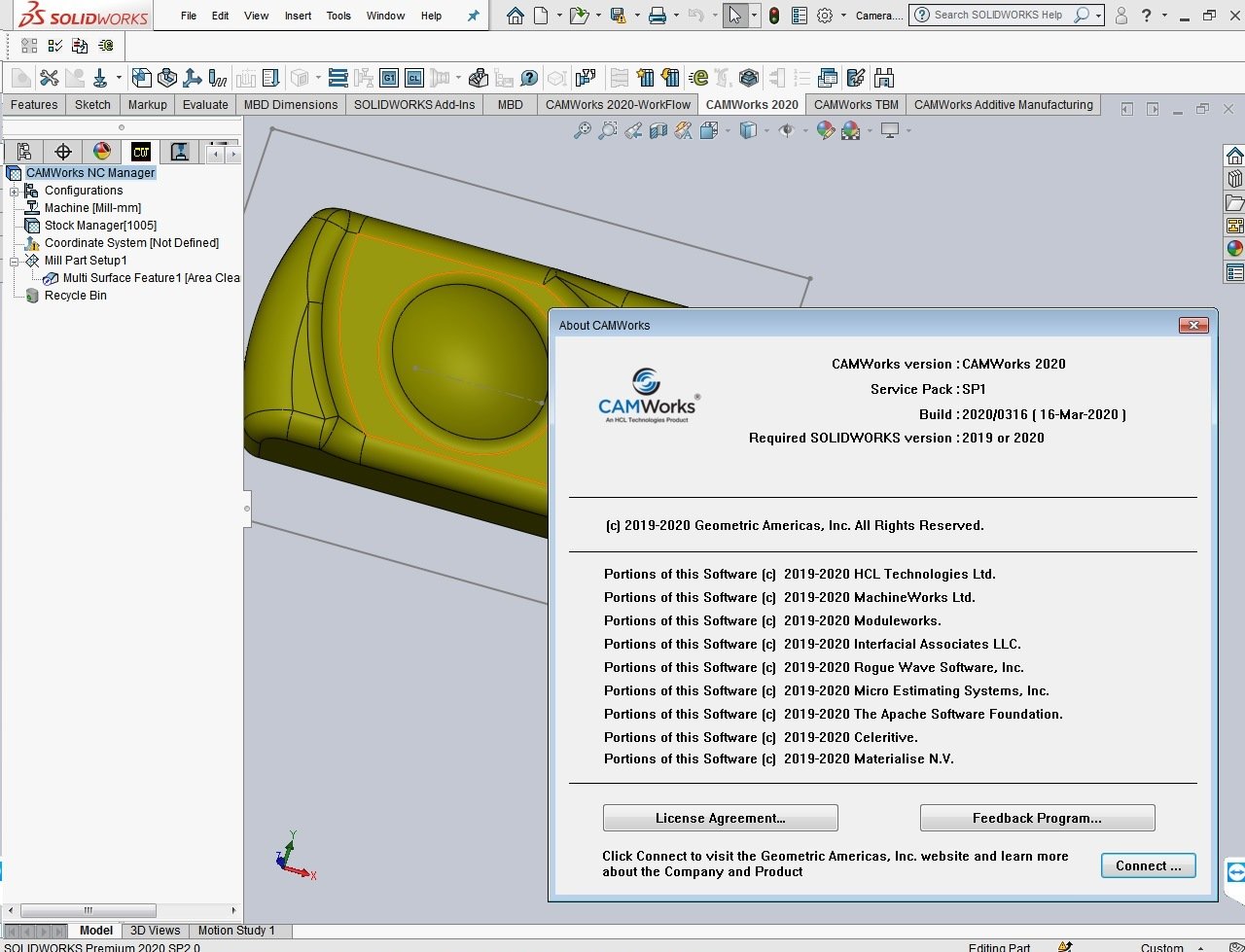

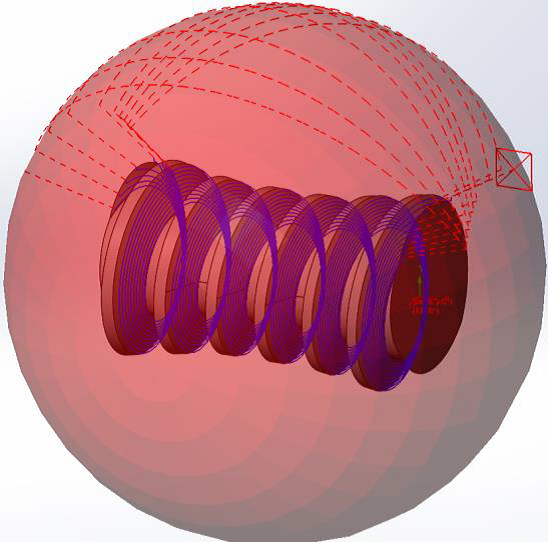

Depths of cut can be constant or variable.HCL Technologies has released CAMWorks Version 2020 with several enhancements to assist machine shops in advancing their smart manufacturing practices. This cycle removes the material between the stock or contain area and the selected feature at decreasing Z depth levels by making a series of parallel cuts across the stock, or by pocketing out toward the stock. What if I need more 3 axis tool paths? Area ClearanceĪrea Clearance is the 3-axis roughing operation. Integrated Tolerance Base Machining (iTBM)Īdvanced 3 Axis Roughing and Finishing Capabilitiesģ Axis Undercutting with Standard and Custom Tools NC Editor with Backplotting – powered by CIMCO But what is included with SOLIDWORKS CAM and CAMWorks? Compare the features in the table below: Productįeature-based machining with feature recognitionĪrea clear roughing, Flat area, and Z level finishing

0 kommentar(er)

0 kommentar(er)